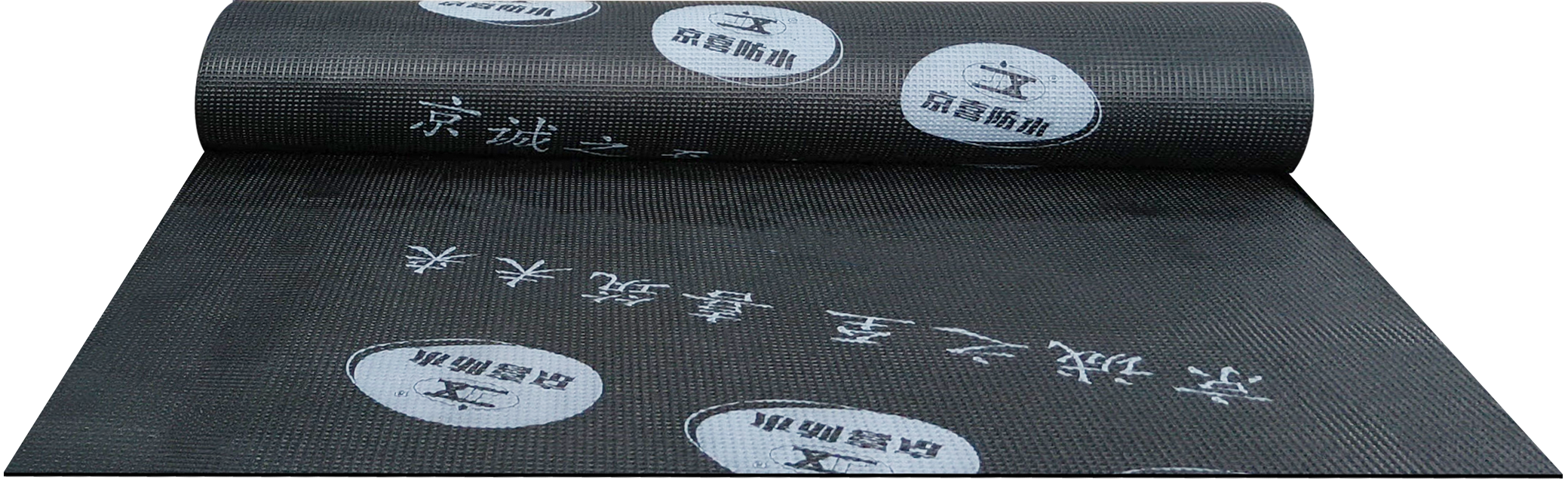

JX-310 Pre-applied polymer-modified bitumen waterproof membrane

Overview

JX-310 Pre-applied polymer-modified bitumen waterproof membrane uses synthetic polymer modified asphalt adhesive as the coating layer, high-strength polyester non-woven fabric as the matrix, natural crystal mineral particles are spread on the upper surface, and the lower surface is covered with an isolation film or PE film. It is a modified asphalt waterproofing membrane constructed by the pre-laid reverse bonding method.

a modified asphalt waterproofingmembrane constructed by the pre-laid reverse bonding method.

Features

1. Excellent impact resistance: The anti-sticking layer is made of natural crystalline mineral particles, which are spread over the asphalt rubber in a flaky shape, effectively resisting damage from object impact.

2. Strong applicability: It has the flexibility and elasticity of modified asphalt, can adapt to the expansion and contraction and cracking deformation of various complex base surfaces, and is not affected by the settlement of the main structure.

3. Good bonding performance: Natural crystalline mineral particles form a concave and convex interface on the surface of the material, which produces physical interaction with the post-poured concrete, forming chemical fusion to promote a close bond between the coiled material and the concrete, blocking the water leakage channel.

4. Convenient construction: It has low requirements on moisture content of the base layer and is not affected by the rainy season. Construction can be carried out on a damp base surface without visible water.

5. Shorten the construction period: The pre-laying reverse-adhesive method is adopted, and no protective layer is required. The steel bars can be directly tied and concrete can be poured above the waterproof layer to speed up the construction progress.6. Excellent dimensional stability: The material has good conformability. After high temperature exposure, the surface of the material has almost no change and does not affect the laying-off parameters.

Specification

Width(m) | Thickness (mm) | Length (m) | Area (m2/roll) |

1m | 4mm | 7.5m | 7.5m2 optional |

Performance Index

China's implementation standard: Q/JXLQ 010-2022"Strong cross-laminated membrane self-adhesive waterproof membrane"

No. | Test items | Technical indicators | |

1 | Soluble matter content | ≥2900g/m 2 | |

2 | Tensile properties | Tensile force | ≥ 1000N/50mm |

Elongation at maximum tension | ≥50% | ||

Stretching phenomenon | There is no separation between the rubber layer and the tire base | ||

3 | Nail rod tearing strength | ≥300N | |

4 | Puncture resistance | ≥5500N | |

5 | Impact resistance (0.5kg.m) | No leakage | |

6 | Static load resistance | 20KG, no leakage | |

7 | Water penetration resistance (hydraulic gradient) | 0.8M Pa/35mm, no water leakage for 4 hours | |

8 | Heat resistance | 7 0℃, no slip, flow or dripping for 2 h | |

9 | Low temperature flexibility | -25℃ , no cracks | |

10 | Oil permeability , number of sheets ≤ | 2 | |

11 | Waterproofness (0.3MPa, 120min) | impermeable | |

12 | Peel strength with post-cast concrete, N/mm | No treatment | ≥1. 7 |

Water treatment | ≥1. 2 | ||

Sediment pollution surface | ≥1. 2 | ||

UV treatment | ≥1. 2 | ||

Heat Treatment | ≥1. 2 | ||

13 | Peel strength after immersion in water with post-cast concrete | ≥1.2 N/mm | |

14 | Coil and Coil Peel strength (lap edge) , N/mm | No treatment | ≥1.5 |

Water treatment | ≥1.5 | ||

15 | Peel strength of anti-adhesive treated part of coil | ≥1.2N/mm | |

16 | Heat aging (80℃, 168h) | Tensile force retention rate | ≥90 % |

Elongation retention rate at maximum tension | ≥80 % | ||

Low temperature flexibility | - 18 ℃, no cracks | ||

17 | Dimensional change rate | ± 0.7% | |

18 | Chemical resistance | Appearance | No cracks, delamination or holes |

Tensile force retention rate | ≥80 % | ||

Elongation retention rate at maximum tension | ≥80 % | ||

Installation

Pre-applied method.

Application

It is mainly used for basement floors and side walls.

Notes

1. Construction is strictly prohibited on rainy, snowydays or days with strong winds of level 5 or above.

2. The construction environment temperature should notbe lower than 5℃.

3. When precipitation occurs during construction,protective measures should be taken for the laid roll materials.

4. In areas with low temperature or large localstress, hot melt construction can be used for paving.